A Comprehensive Guide to Welding Inspection Madison Criteria

Recognizing the Basics of Welding Evaluation to Guarantee Quality and Safety

In the realm of modern engineering, welding examination stands as a cornerstone for making sure both the quality and security of architectural creations. What are the subtleties of these inspection techniques that make them crucial for maintaining architectural honesty?

Value of Welding Examination

In the world of commercial fabrication, the significance of welding evaluation can not be overstated. Welding inspection plays a vital role in making sure the stability, security, and long life of welded structures. Given the diverse applications of welding in industries such as construction, automotive, aerospace, and shipbuilding, the need for stringent quality assurance measures is paramount. Correct inspection ensures that welds meet defined codes and criteria, which is crucial for protecting against architectural failures that could result in devastating consequences.

The process of welding naturally entails complex variables, consisting of temperature, material residential properties, and ecological conditions, every one of which can influence the quality of the weld. A comprehensive evaluation identifies issues such as fractures, porosity, and incomplete combination, which can compromise the toughness and reliability of the weld. By spotting these concerns early, rehabilitative activities can be taken, therefore decreasing the risk of failure and associated costs.

In addition, welding inspection contributes to regulatory compliance, as numerous sectors are controlled by strict safety and security standards and standards. Failing to follow these guidelines can cause legal responsibilities and punitive damages. Inevitably, welding evaluation not just safeguards physical frameworks but also promotes and protects human lives market online reputations.

Key Welding Assessment Approaches

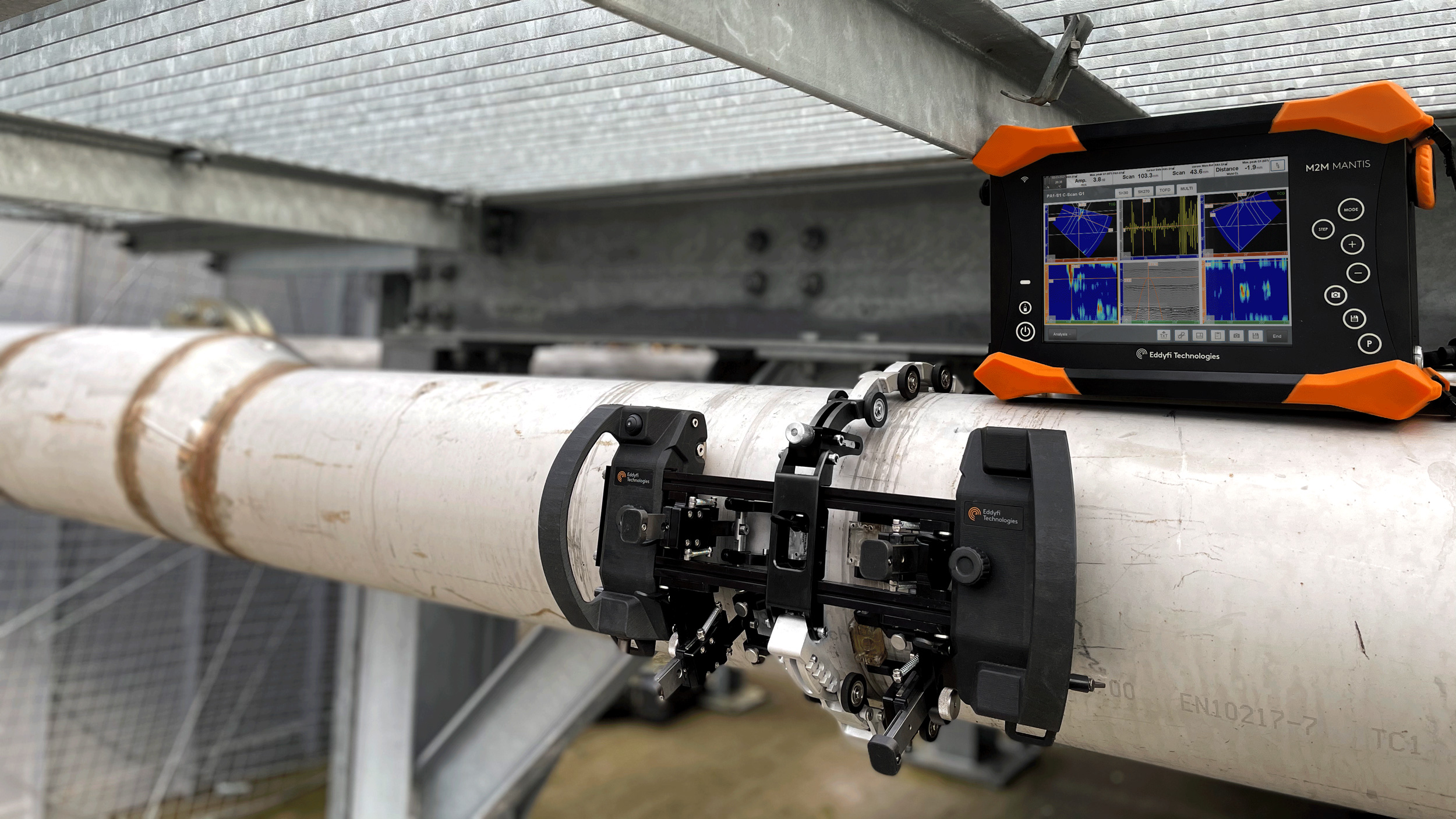

Although welding inspection is crucial to guaranteeing the high quality and security of bonded frameworks, it is the certain techniques utilized that figure out the performance of the examination procedure. Trick welding assessment approaches can be extensively classified into non-destructive testing (NDT) and damaging testing. Non-destructive testing approaches such as aesthetic assessment, ultrasonic screening, radiographic testing, magnetic bit testing, and liquid penetrant screening are primarily made use of to review the homes of a weld without causing damage. Aesthetic examination is typically the initial step, involving an extensive evaluation of the weld's surface for issues like fractures or porosity.

Radiographic and ultrasonic testing are a lot more advanced methods that allow assessors to evaluate the inner stability of the weld. Ultrasonic screening utilizes high-frequency acoustic waves to discover stoppages, while radiographic screening utilizes X-rays or gamma rays to create a photo of the weld's interior. Magnetic bit screening and fluid penetrant testing are surface examination techniques made use of to locate surface area and near-surface flaws. On the other hand, destructive screening approaches involve literally damaging or cutting the weld to evaluate its mechanical residential or commercial properties. These comprehensive evaluation approaches ensure that welds satisfy market criteria and safety needs, thereby making certain structural stability and efficiency.

Duty of Qualified Assessors

Qualified inspectors play a pivotal role in the welding evaluation process, ensuring that all welds follow stringent sector criteria and safety and security policies. Their expertise is essential in identifying defects or abnormalities that might endanger the structural stability of a weld. By carefully analyzing each weld, certified inspectors help protect against possible failures that could lead to hazardous accidents or pricey repair work.

To become qualified, assessors need to undergo rigorous training and screening, which familiarizes them with numerous welding methods, materials, and screening techniques. This extensive expertise enables them to evaluate weld high quality efficiently and make educated judgments regarding their safety and integrity. Licensed assessors are skilled in analyzing specifications and blueprints, making certain that the welding work straightens with the project's style needs.

An essential component of their duty is to record their browse around this site findings completely, giving a thorough document of the inspection process. Their contribution is vital in keeping high degrees of high quality and safety and security in welding operations.

Devices Utilized in Welding Evaluation

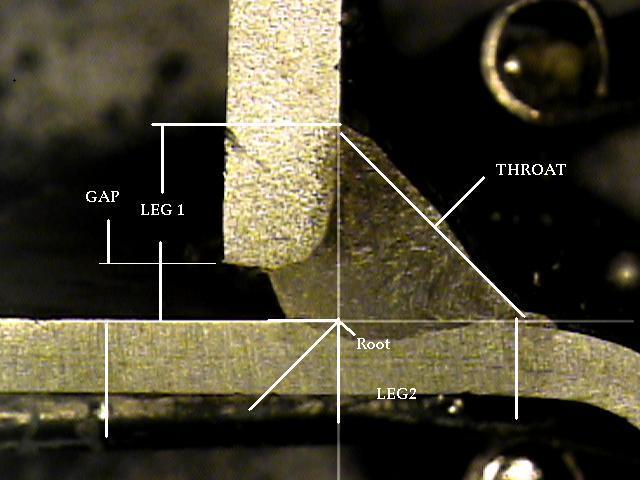

Welding examiners depend on a variety of specialized devices to perform their duties effectively, making certain each weld satisfies the required standards. Amongst these tools, aesthetic assessment aids like multiplying glasses and mirrors are basic, enabling assessors Our site to closely take a look at welds for surface area defects such as cracks, porosity, and undercut. Calipers and fillet weld evaluates are necessary for gauging weld measurements to confirm compliance with layout requirements.

Advanced tools prolong past visual help, including non-destructive testing (NDT) equipment. Ultrasonic testing devices are critical in identifying subsurface problems, utilizing acoustic waves to reveal inner gaps without compromising the weld's stability. Radiographic testing utilizes X-rays or gamma rays to record images of a weld's inside, highlighting potential problems.

Magnetic fragment screening is one more critical tool, especially for detecting surface and near-surface stoppages in ferromagnetic materials. By applying ferrous particles and magnetic fields, assessors can recognize defects that may or else be invisible.

Dye penetrant evaluation is commonly made use of for non-ferrous materials, offering a contrast-enhanced visual check for surface-breaking problems. Welding Inspection Madison. Together, these tools allow welding assessors to adequately assess weld quality, making sure safety and security and integrity in numerous applications across sectors

Ensuring Structural Integrity

Welding procedures have to follow established her latest blog criteria and codes, such as those specified by the American Welding Culture (AWS) or the International Organization for Standardization (ISO) These standards guarantee that the welds can withstand ecological elements and functional tensions. Certified and certified welders play a critical role in this procedure, as their competence ensures that methods are used correctly, lessening defects such as splits, porosity, and incomplete combination.

Post-weld examination is another crucial component of confirming architectural integrity. Non-destructive testing (NDT) approaches, consisting of ultrasonic testing and radiographic testing, are used to spot subsurface problems without endangering the welded structure. These assessments confirm that the welds meet the required high quality criteria, providing assurance of their sturdiness and integrity. Ultimately, guaranteeing structural stability in welding not just safeguards human lives yet also protects investments and improves the durability of crafted frameworks.

Final Thought

The fundamentals of welding examination are vital for keeping the high quality and security of welded frameworks. By carrying out essential examination approaches, such as aesthetic assessments and non-destructive testing, potential defects that might jeopardize architectural honesty are identified. Qualified assessors are important in making sure compliance with sector requirements and effective interaction among stakeholders. The usage of specialized devices further boosts the assessment process, inevitably protecting human lives and lengthening the life expectancy of bonded buildings.

Welding inspection plays an important duty in making sure the honesty, safety, and durability of bonded frameworks.Although welding evaluation is important to ensuring the high quality and safety and security of welded structures, it is the certain approaches used that establish the effectiveness of the assessment procedure. Trick welding inspection techniques can be extensively classified right into non-destructive screening (NDT) and destructive testing.Licensed examiners play an essential duty in the welding examination procedure, ensuring that all welds comply with strict market requirements and safety and security laws.The fundamentals of welding inspection are necessary for keeping the top quality and safety and security of bonded frameworks.